Watana Bhand Packaging System Co., Ltd.

Machine & System

Return to previous page

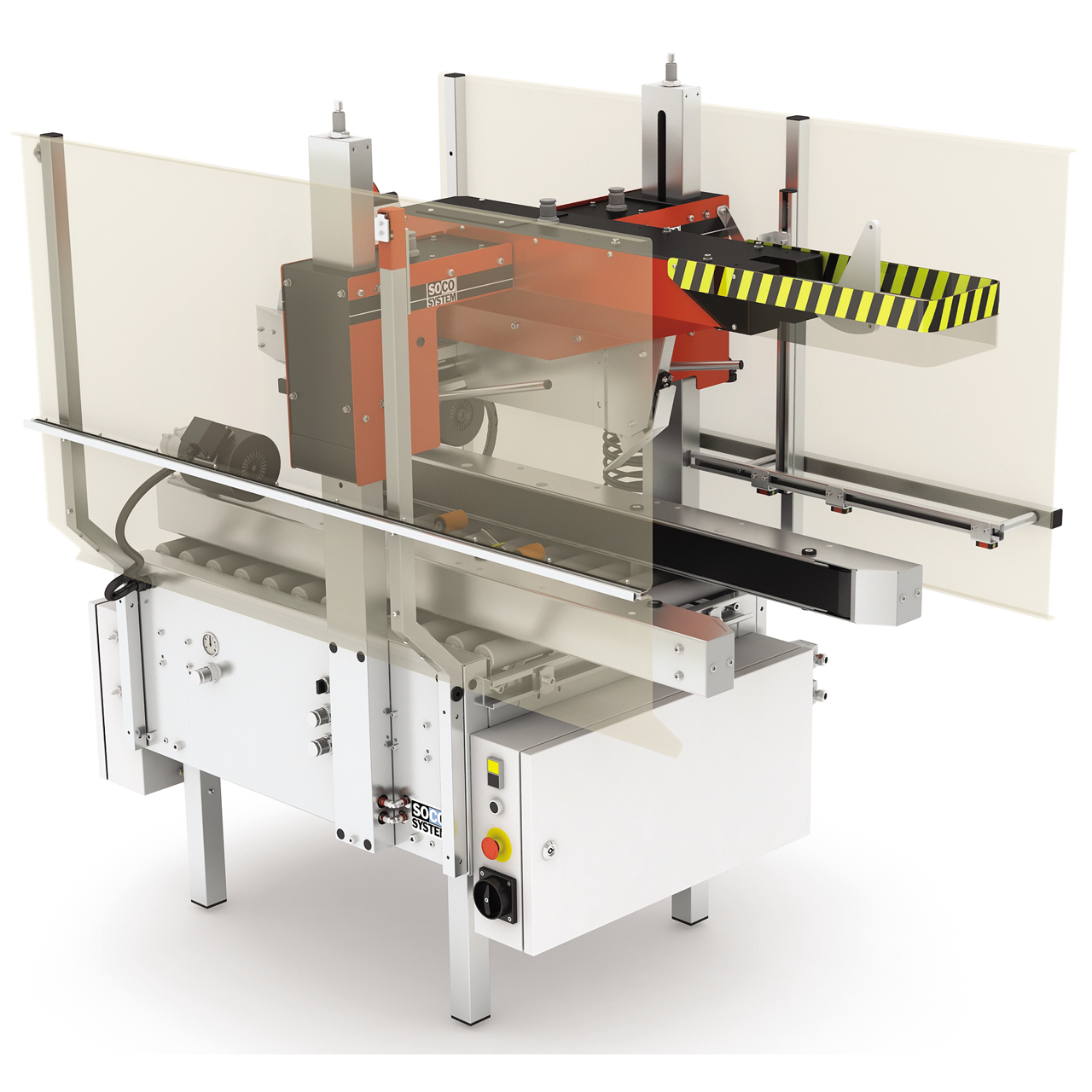

SOCO T-400 carton sealer guarantees high production capacity and maximum space utilization.

The model is ideal for integration into fully automatic packaging lines of uniform cases in batches. The standard version is available in three constructions, all can be fitted with extra high pillars. With it compact design, user can easily adjust different carton sizes and replace tape and dispenser. When combined with feed-in control function, the model ensures efficient separation and maximum utilization of its capacity.

Read more

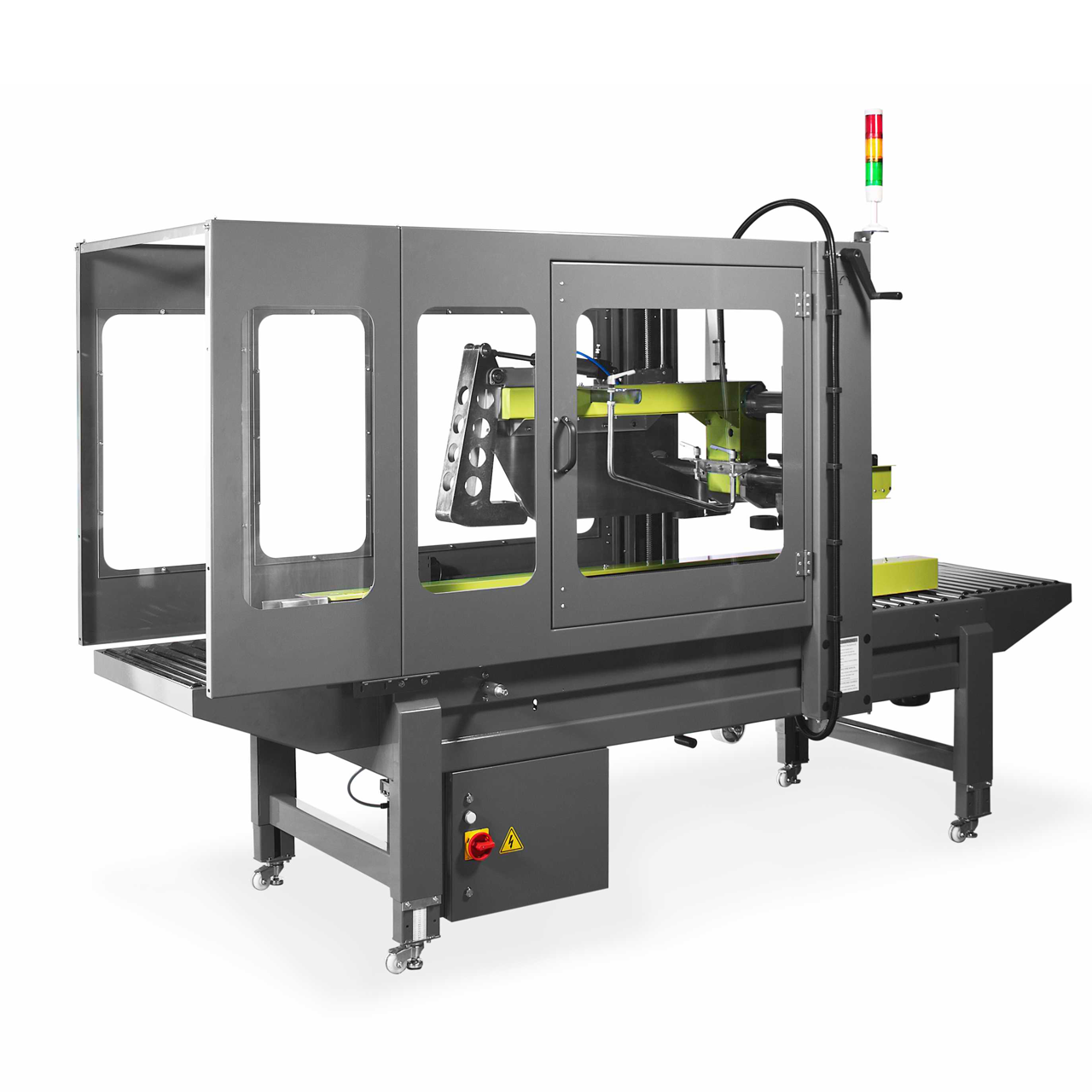

SOCO T-55 carton sealer comes in compact design. The automatic height and width adjustment makes the model ideal in packing lines where carton sizes vary. For example, in the dispatch department of warehouses, two operators can work simultaneously on either side of the packing table. The T-55 can operate as a fully automatic top and bottom sealer provided the top flaps of the case are closed by means of a control label or a small piece of tape.

Read more

00:00

--

/

--

SOCO T100 carton sealer is suitable for handling smaller shipping cases and retail distribution. All important components, including dispensers, belt drives, and top assembly, are of SOCO SYSTEM’s well known quality. The T-100 is available with an electro-zinc or a stainless steel finish. In the stainless steel version, all external parts are made of stainless steel, except for gears, motors, and aluminum parts. The machine is easy to clean and resistant to humidity.

Read more

00:00

--

/

--

EXC-128SDF automatic carton sealer comes in compact design and allows automatic adjustment of carton width and height. The body height can be adjusted to connect to production line conveyor. Equipped with side belt and pneumatic system, the machine ensures perfect sealing with no carton damage.

Read more

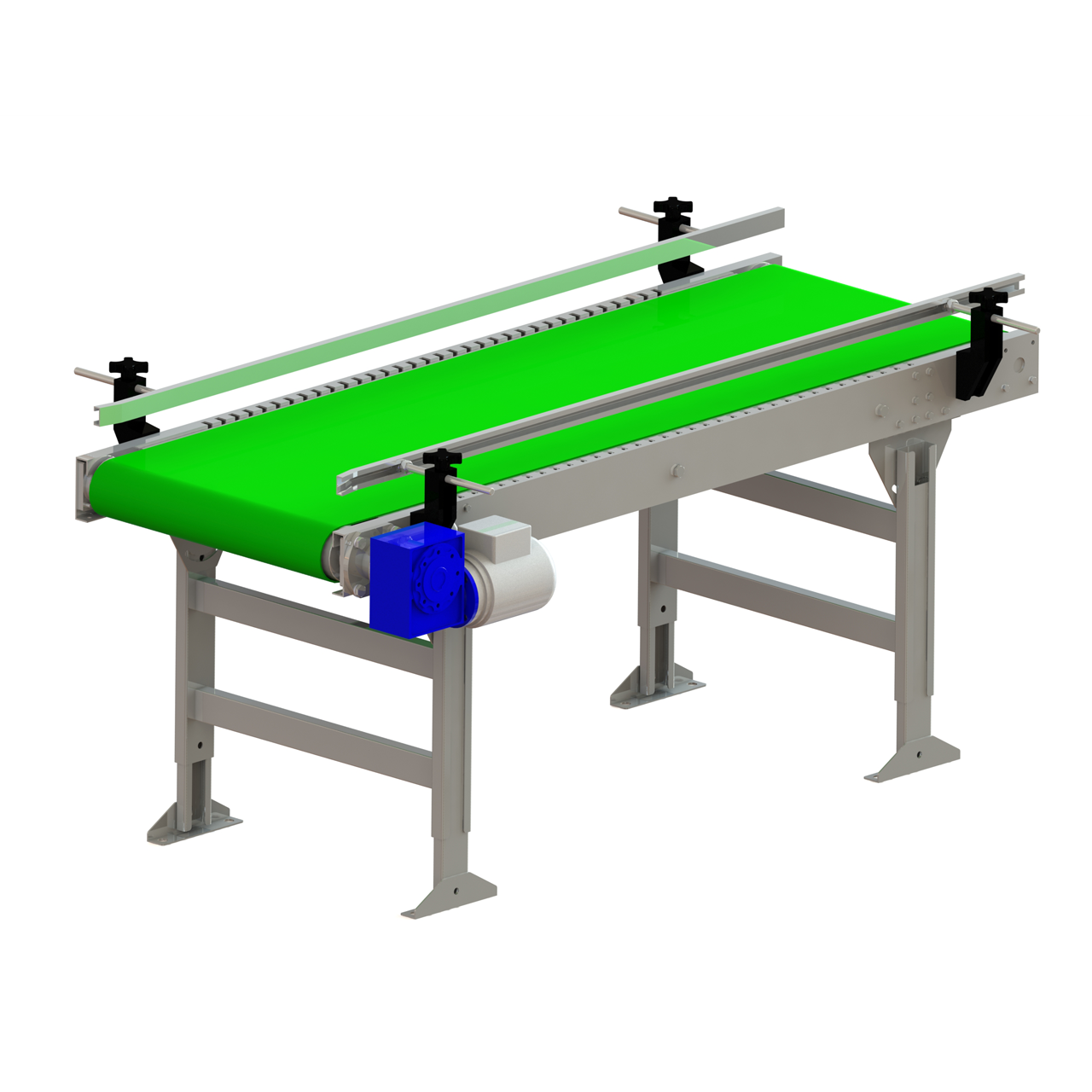

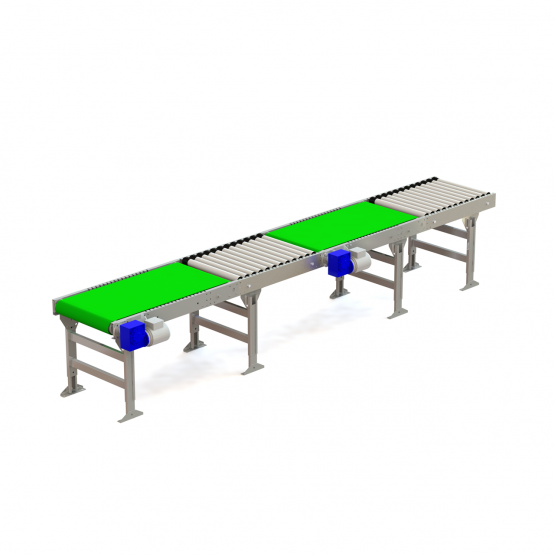

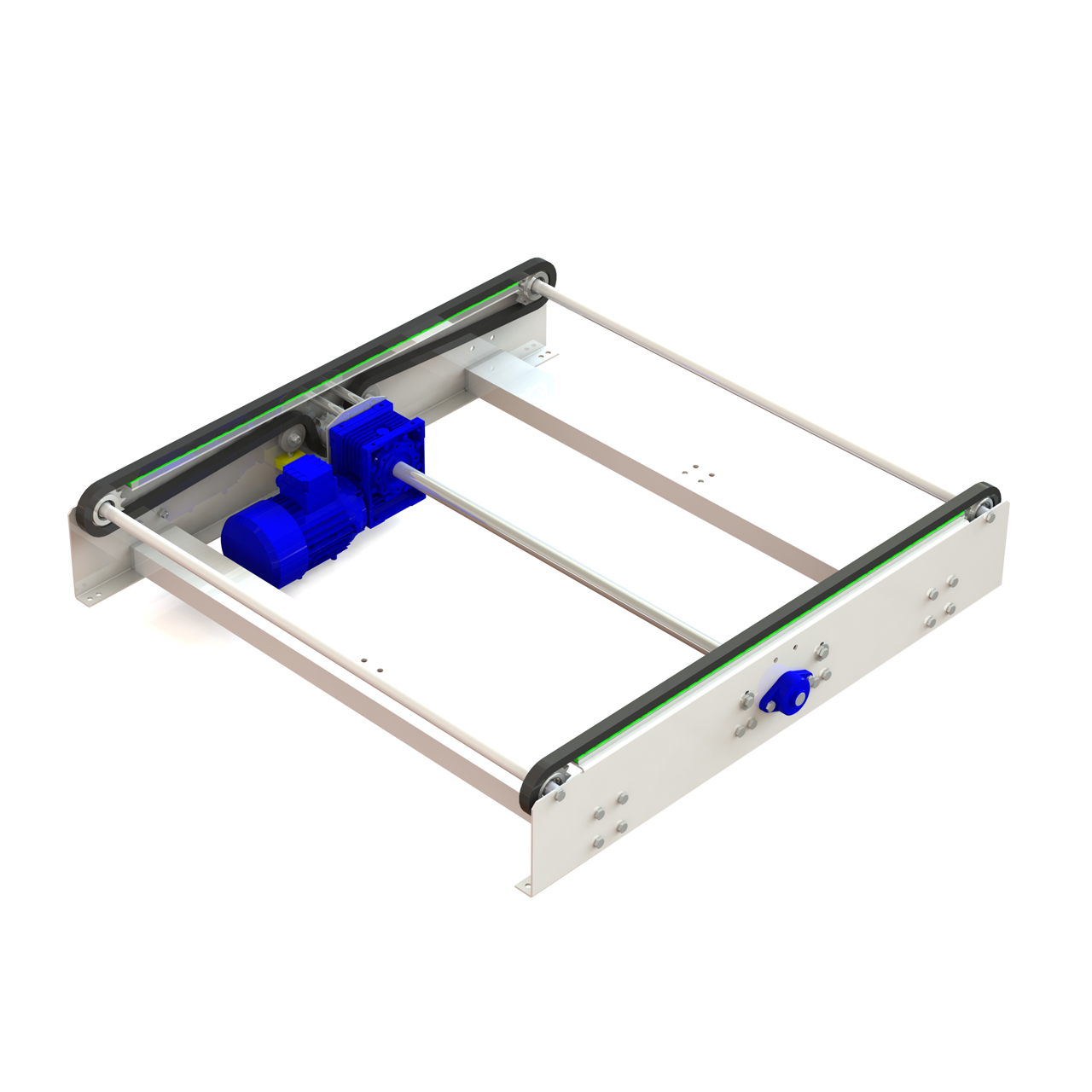

Belt Conveyors with underlying drive and tension section

The conveying system is highly beneficial for large quantity packaging as it facilitates the transfer of goods between each process which includes the transfer of package to or from manufacturing process, the transfer of package from one process to another, as well as the transfer of package from forming to filling process. You can be sure that everything will be efficiently and accurately conveyed to its correct destination.

Read more

The conveying system is highly beneficial for large quantity packaging as it facilitates the transfer of goods between each process which includes the transfer of package to or from manufacturing process, the transfer of package from one process to another, as well as the transfer of package from forming to filling process. You can be sure that everything will be efficiently and accurately conveyed to its correct destination.

Read more

ระบบการลำเลียง เหมาะสำหรับบรรจุภัณฑ์จำนวนมากมีความสำคัญต่อการถ่ายโอนวัสดุระหว่างกระบวนการผลิตอย่างมีประสิทธิภาพ ไม่ว่าจะเป็นการเคลื่อนย้ายภาชนะบรรจุวัสดุเข้าหรือออกจากการผลิตการนำภาชนะมาจากกระบวนการผลิตไปจนถึงกระบวนการผลิตหรือจากการแปรรูปไปจนถึงบรรจุภัณฑ์ระบบลำเลียง มั่นใจได้ว่าวัสดุจะถูกเคลื่อนย้ายได้อย่างมีประสิทธิภาพและถูกต้อง

Read more

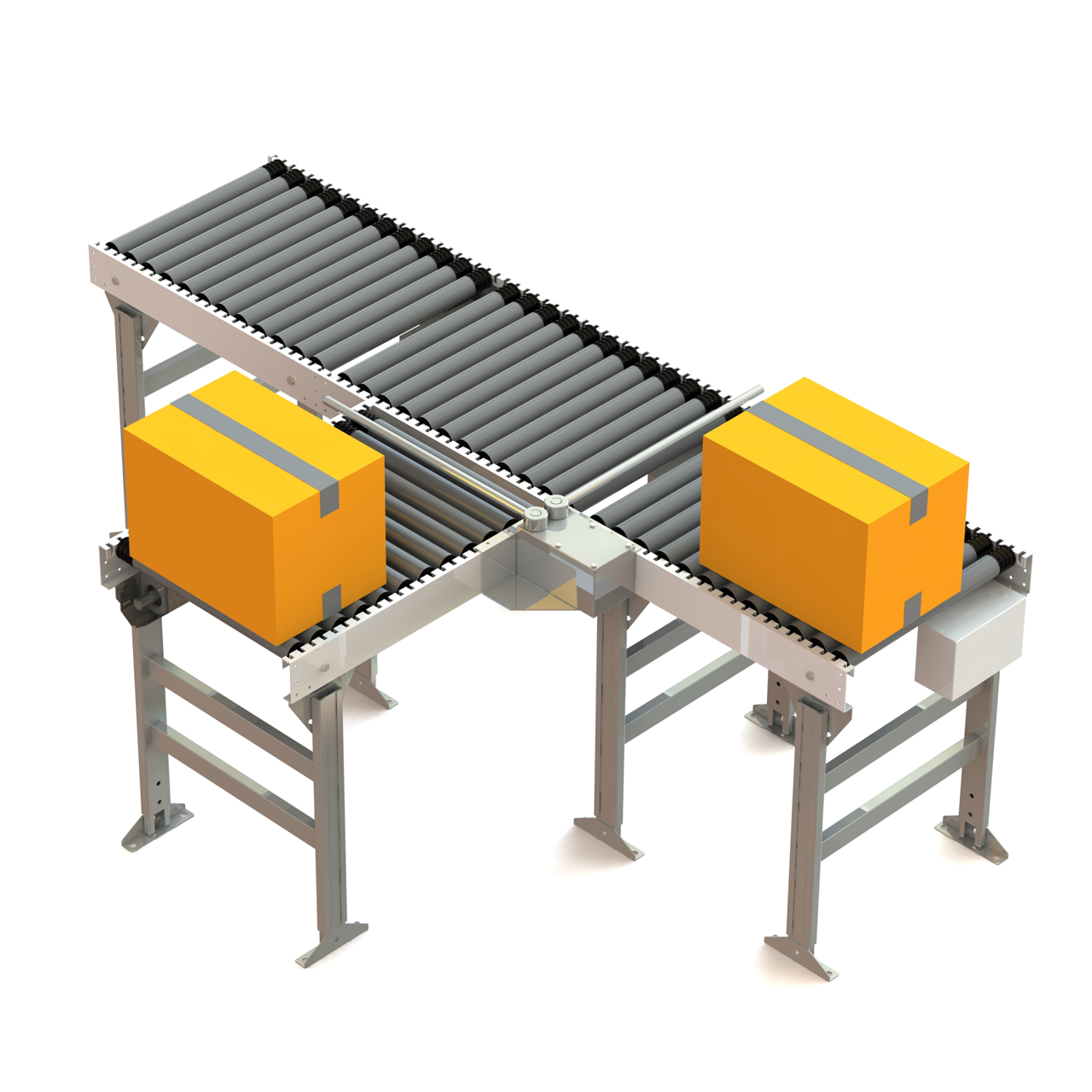

Carton Holder with plastic laminated plate

ระบบการลำเลียง เหมาะสำหรับบรรจุภัณฑ์จำนวนมากมีความสำคัญต่อการถ่ายโอนวัสดุระหว่างกระบวนการผลิตอย่างมีประสิทธิภาพ ไม่ว่าจะเป็นการเคลื่อนย้ายภาชนะบรรจุวัสดุเข้าหรือออกจากการผลิตการนำภาชนะมาจากกระบวนการผลิตไปจนถึงกระบวนการผลิตหรือจากการแปรรูปไปจนถึงบรรจุภัณฑ์ระบบลำเลียง มั่นใจได้ว่าวัสดุจะถูกเคลื่อนย้ายได้อย่างมีประสิทธิภาพและถูกต้อง

Read more